The metal spinning machine is a technology that rotates the force point from point to line and from line to surface, and at the same time applies a certain pressure in a certain direction to make the metal material deform and flow along this direction to form a certain shape.

CNCMACHINE.WIKI

List of Contents

What Is Spinning Technology?

It is also called metal spinning technology. Here, the metal material must have plastic deformation or flow properties. Spinning is not equivalent to plastic deformation. It is a complex process that combines plastic deformation and flow deformation. It is particularly important to point out that the spinning technology we are talking about is not a single high-power spinning and ordinary spinning, but a combination of the two. High-power spinning is used for the processing technology of spinning shells of various cylinders and cone-shaped special-shaped bodies. It is a relatively old and mature method and process, also called rolling method.

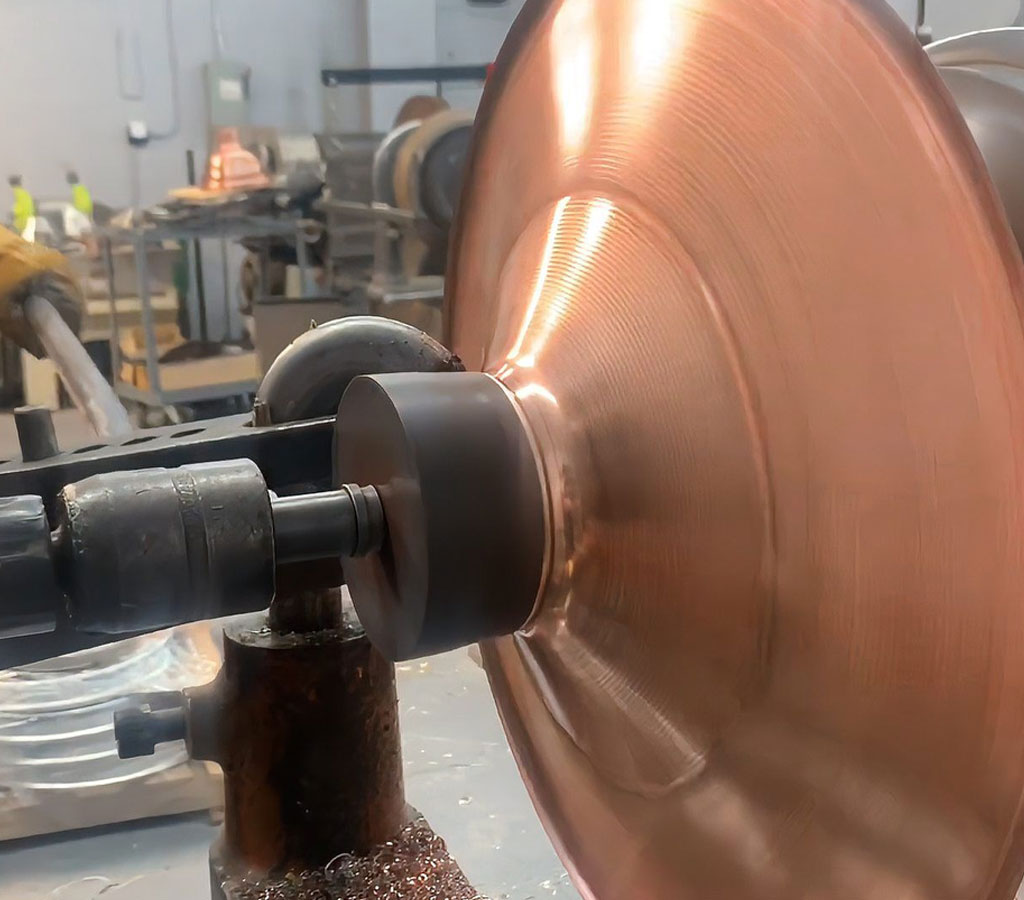

Metal Spinning means that after the sheet metal blank is clamped in the axial direction of the forming die, the Mold and the blank rotate under the biaxial drive, and are continuously squeezed by the forming wheel in the radial direction, so that the metal blank is gradually deformed and finally on the axial surface A process in which both the outer surface of the cylinder and the outer surface of the cylinder form the desired shape.

The metal spinning forming process is the flow and plastic deformation of the metal. The material of the metal blank, the spinning forming wheel, the spinning pressure and the feed speed are appropriately selected, which can form a metal surface with strong hardness, high wear resistance and high smoothness on the molding surface. .

The runout accuracy of the formed bus bar relative to the shaft core can reach 0.02mm. This molding method is suitable for rotating parts with complex shapes on the surface. Such as: toothed belt pulleys, multi-ribbed groove belt pulleys, etc.Metal Spinning China Company provides the latest technology in metal stamping, deep drawing, CNC machining centers and PNC automatic spinning lathes. We are nationally known for our quality workmanship and customer service.

How Do Metal Spinning Machine Works

Ordinary spinning is referred to as general spinning, which can complete various tasks such as deep drawing, rib pressing, closing, sealing, flanging, and curling. The ordinary spinning forming process is shown in Figure 2-1. Ordinary spinning workpieces have different shapes, all of which are axisymmetric hollow rotating bodies, so they have a wide range of uses. There are forming processes such as shrinking, expanding, and curling.

Ordinary spinning includes overall forming and local forming. On modern spinning machines, cold spinning and hot spinning can be used to perform corresponding plastic forming according to the different technical requirements of workpieces of different specifications; the main categories are various processing forms such as drawing, shrinking, expanding, and stem making.

There are generally three basic forms of spinning pulleys: folding pulleys, split pulleys, and rolled multi-V pulleys (also called multi-V pulleys).

Compared with cast iron pulleys, the advantages of spinning pulleys are that they are made by spinning technology (chipless processing), light structure, and material saving, so the moment of inertia is small. It is a new product that saves materials and energy. High production efficiency (2 to 4 pieces per minute), good balance performance, generally no balancing treatment is required. Since the material flow line is not cut off, the surface is cold-worked and hardened, the density of the organization is improved, the strength and hardness of the wheel groove surface are improved, and the dimensional accuracy is high, the slip difference between the V-belt and the wheel groove is small, and the belt life is long.

The pulley spinning process and equipment is an advanced technology. The pulley spinning process has achieved a series of scientific research results such as folded pulleys, split pulleys, rolled multi-V pulleys and combined pulleys. Various technical problems in spinning forming have been solved in both theory and practice, and have been successfully used in production.

Basic Procedures For The Operation Of CNC Spinning Machines.

Nowadays, CNC spinning machines basically adopt man-machine interface operation mode, which is simple and easy to use. Reasonable operation mode can not only ensure the durability and stability of the equipment, but also improve production efficiency and ensure production safety.

Matters needing attention during operation of CNC spinning machine:

- 1. Check whether the proximity switch of each function is effective, and prevent the processing program from being unable to work due to the loose or damage of the proximity switch;

- 2. When the emergency button is pressed, the operation selection switch on the operation surface must be adjusted to the manual position. After troubleshooting, in the manual state, restore the original work positions and continue processing.

Maintenance schedule of CNC spinning machine:

- 1. It is necessary to check the lubricating oil level and coordinate axis position before use, and check whether the direction of movement is barrier-free;

- 2. Check whether the fasteners are loose, and whether the typical parts are firm and reliable;

- 3. After starting the system, troubleshoot the alarm situation;

- 4. Start the spindle system, hydraulic station, and jog to run all actions;

- 5. Run the machine empty for 2-3 minutes, and check whether the machine lubrication, vibration, cooling, and noise are normal;

- 6. During operation, if the power meter encounters any abnormality, it needs to be shut down immediately;

- 7. After the equipment is used, the machine site should be kept clean and tidy;

- 8. Do a good job handover carefully, summarize the problems that occurred during the operation of the equipment and explain to the handover personnel to ensure the normal operation of the equipment

The CNC spinning machine is generally composed of the main body, the spindle box, the rotating shaft seat, the tailstock and other main components. In the spinning process, the blank (plate or ring) is clamped

Tighten the Mold to make it rotate, and press and press the spinning wheel, so that the blank is continuously deformed point by point and becomes a workpiece.

- Uses: This CNC spinning machine is suitable for industries such as lamps, cookware, tableware, and handicrafts. Can complete barrel type, cone type, parabolic type, la

- Batch production of horn type and warhead type products.

- Features: This CNC spinning machine is economical. Mainly for the products of copper, iron, aluminum, and stainless steel materials, flat knives, sharp knives, repairing

- Edge knives and crimping knives. It solves the difficulty that other brands of CNC spinning machines cannot process various materials and various shapes.

- Spinning range: Diameter of blank: 500MM Thickness of aluminum: 0.5-4mm. Thickness of iron sheet: 0.5-2mm. Copper sheet thickness: 0.5-1.5mm.

- Thickness of stainless steel sheet: 0.5-1.5mm.

- CNC spinning equipment is suitable for the processing of metal spinning parts and pipe fittings such as iron, aluminum and copper, and is widely used in lighting, handicrafts, furniture, automobiles and other industries. The tools used are wide and flexible, and have high production efficiency. It can complete a series of molds (such as barrel, cone, parabolic, trumpet, bullet, etc.) and multiple molds (such as vases, gourds, round balls, etc.). Type, etc.) mass production.

Product Description

- 1. With mature CAD drawing programming software function, the motion track of the rotary wheel can be straight line, arc, multi-arc connecting line and combined curve

- Lines, etc., and input into the computer for standardized programming of passes.

- 2. The operator can input process parameters and spinning passes through the keyboard and operation panel, and can edit, store and recall at will.

- 3. It has the “copy” protection function of the core mold contour, that is, the rotating wheel will not collide with the core mold during process adjustment and recording and teaching.

- 4. The machine tool can pause the feed rate and spindle speed in the automatic program. With stroke limit protection, the software and hardware in the control system are extremely

- Limit protection, fault detection and alarm functions.

- 5. Automatic detection of failures, automatic diagnosis and overload protection for each unit when starting up.

- 6. According to the requirements of users, spinning forming of parts of various special shapes can be realized to ensure the relevant dimensions of the workpiece shape, diameter, thinning rate, etc.

- 7. Finish trimming, flanging, crimping, necking, rolling, finishing shape and thread processing in the same machine tool.

About BE-CU Spinning Cmpany

BE-CU Metal Spinning Company was founded over 25 years ago and has built an outstanding reputation as a supplier of smaller lot and large diameter metal spinnings. Our specialized equipment can spin blanks up to 120″ in diameter and up to .135″ thick. We are a key supplier to the farm and construction equipment, food service, air handling and cryogenics industries.

In order to better serve our customers we operate our own tool and die facility and make all of our own tooling in-house. Since many of the tools (forms) used to spin large diameter spinnings are made from a special bonded wood composite, we maintain the largest inventory of these wood forms in the Midwest. In several commonly used shapes, such as tank heads and hemispheres, we have pre-made tools in many sizes which can further reduce our customer’s tooling costs.

We are also able to offer a wide range of additional forming such as metal stamping, deep drawing and machining through our affiliate BE-CU PROTOTYPE. By providing these services in-house, we avoid the lengthy delays and increased costs incurred by using outside contractors. We can also ensure higher quality throughout the production process and guarantee your satisfaction with the finished product. Dedicated professionals, skilled BE-CU and our commitment to customer service has enabled us to make this guarantee for over 25 years.

Please keep the source and address of this article for reprinting:CNC Spinning Machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machine Wiki,Thanks!^^