What Is CNC Grinding Machine?The CNC grinder is a machine tool that uses abrasive tools to grind the surface of the workpiece through CNC technology. Most of the grinders use high-speed rotating grinding wheels for grinding processing, a few use other abrasive tools such as oilstone, belts and free abrasives for processing, such as honing machines, super-finishing machine tools, belt grinders, grinders and polishing Machine waiting. CNC grinding machines include CNC surface grinders, CNC centerless grinders, CNC internal and external cylindrical grinders, CNC vertical universal grinders, CNC coordinate grinders, CNC forming grinders, etc.

The grinder can process materials with higher hardness, such as hardened steel, cemented carbide, etc.; it can also process brittle materials, such as glass and granite. The grinder can perform high-precision and small surface roughness grinding, and can also perform high-efficiency grinding, such as powerful grinding.

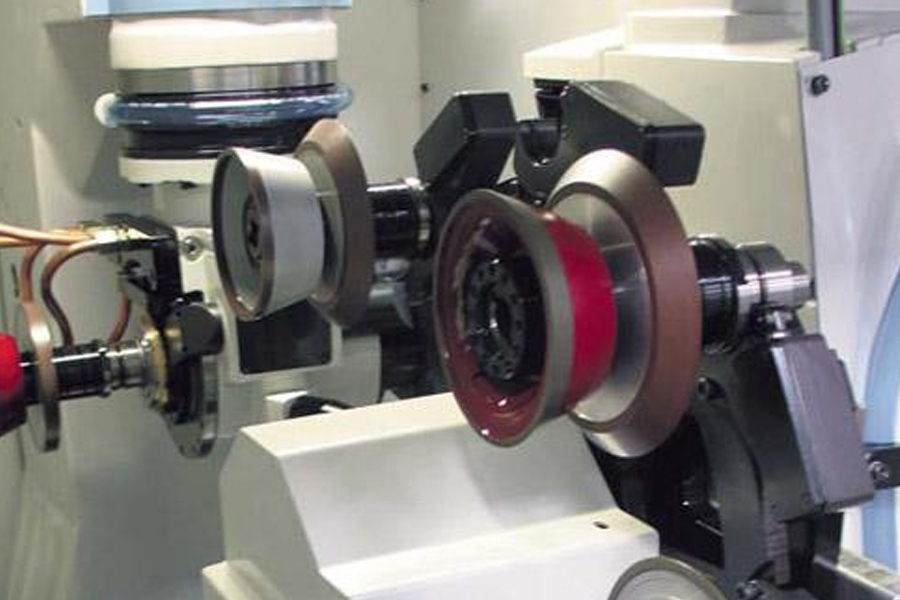

CNC Grinding Machine

Cnc machines tools are the product of the combination of information technology and mechanical manufacturing technology, and represent the technical level and development trend of modern basic machinery. China’s cnc machine tool industry is developing rapidly, and there are nearly 100 CNC machine tool manufacturers. In order to accelerate the development of China’s CNC machine tool industry and better meet the needs of national economic development, China has listed important basic machinery as one of the four key areas of revitalization in the “Machinery Industry Revitalization Program” formulated and issued, and the important foundation Machinery is mainly the development of CNC machine tools. The development policy of my country’s CNC machine tools before the “Ninth Five-Year Plan” and 2010 is to focus on six types of mainframes: CNC lathes, machining centers, CNC grinders, CNC forging machine tools, CNC heavy-duty machine tools, and CNC precision electrical machine tools. Focus on breakthroughs in numerical control systems; develop popular models to improve reliability; integrate internal and external to realize the industrialization of China’s data-controlled machine tools. During the “Ninth Five-Year Plan” period, the focus is on improving reliability, increasing varieties, and popularizing CNC systems and CNC machine tools to achieve economic scale production. By 2000, the number of CNC machine tools had grown to 1,000 varieties, of which 100 had reached the international level in the early 1990s. The mean time between failures of CNC machine tools and CNC systems has reached 10,000 hours, and the annual output has reached 20,000 units.

List of Contents

The History Of The Grinder

- In the 1830s, in order to adapt to the hardened processing of parts such as clocks, bicycles, sewing machines and firearms, Britain, Germany and the United States developed grinders using natural abrasive wheels. These grinders were made by adding grinding heads to existing machine tools such as lathes and planers. They were simple in structure, low in rigidity, and prone to vibration during grinding, requiring operators to have a high level of skill to achieve precision. Artifacts.

- The Universal Cylindrical Grinding Machine manufactured by Brown-Sharp Company of the United States, exhibited at the Paris Exposition in 1876, was the first machine with the basic characteristics of a modern grinding machine. Its workpiece headstock and tailstock are installed on a reciprocating worktable. The box-shaped bed improves the rigidity of the machine tool and is equipped with internal grinding accessories.

- In 1883, Brown-Sharp Company of the United States made a surface grinder with the grinding head mounted on the column and the worktable moving back and forth.

- Around 1900, the development of artificial abrasives and the application of hydraulic transmission greatly promoted the development of grinders. With the development of modern industry, especially the automobile industry, various types of grinders have come out one after another. For example, at the beginning of the 20th century, planetary internal grinders, crankshaft grinders, camshaft grinders and piston ring grinders with electromagnetic chucks were developed successively for machining cylinder blocks.

- The automatic measuring device was applied to the grinder in 1908.

- Around 1920, centerless grinders, double-face grinders, roll grinders, guideway grinders, honing machines and super-finishing machine tools were successively manufactured and used;

- In the 1950s, a high-precision cylindrical grinder for mirror grinding appeared;

- At the end of the 1960s, high-speed cnc grinding machine with a grinding wheel linear speed of 60-80 m/s and large cutting depth, slow-feed grinding surface grinders appeared;

- In the 1970s, technologies such as digital control and adaptive control using microprocessors were widely used on grinders.

The Related Issues Of Grinding Machine

The Related Issues Of Grinding Machine

In the process of the operation of CNC machine tools, it is found that there are some hidden dangers in the use of existing CNC machine tools compared with teaching and student training, which must be paid attention to.

1.Background Editing

In the FANUC series oi Mate TB system, the manufacturer has set up a background editing function in order to facilitate the processing by the operator, that is, during the automatic processing process, the current program can be modified in the program editing mode without terminating the processing. Or edit other programs in the background; you can also select the control mode to “handwheel mode”, and move the tool by shaking the handwheel to change the position of the processing point. The background editing function is convenient for the operator to modify the processed parts during the processing, which simplifies the operation process. However, this simplification has brought a serious hidden danger to safe operation. In teaching practice, students are prone to misuse. When the control mode is selected to “automatic cycle” mode, if the chuck of the machine tool is not clamped or the tailstock is not ejected (that is, the machine tool is not ready), press the “Cycle Start” key and the machine tool will not operate. At this time, select the control mode to “manual operation” to make the machine chuck clamp and the tailstock ejected (that is, the machine is ready), then the “Cycle Start” command just selected is valid and the program is automatically executed. If the operator is loading the material at this time, the hand has not left the workpiece, and there is a spindle start command in the program, the operator is very susceptible to hand injury, and even serious safety accidents may occur. The solution is as follows: The manufacturer adjusts the ladder diagram of the system to change the start condition of the “Cycle Start” key, that is, when the “Chuck Clamping” and “Tailstock Top Tightening” are ready, the “Automatic Cycle” is required. Or the “Cycle Start” key can only work in the “MDI” mode. The absence of any of them will be invalid. The “or” relationship is converted into the relationship of chuck clamping→tailstock tightening→automatic mode→cycle start “parallel” relationship. However, this kind of change will make the “back-end editing function” useless, and it will bring difficulties when the operator needs to change the program while processing, but this change is very necessary in the mechanical engineering training teaching that pays more attention to safety. 2) Cancel the existing command. After pressing the “Cycle Start” button in the “automatic mode” is invalid, then press the “reset” button to cancel the existing command, even if the “chuck clamping”, “tailstock tightening”, and “automatic mode” programs will not automatically To execute, you need to re-operate the “Cycle Start” key. This method eliminates the danger in the bud and is worthy of being promoted in application.

2.Machine Power

The CNC machine tool is equipped with an NC system (digital control system), and the NC data is required to be effectively saved when the machine is shut down. Therefore, the NC system has its own backup power supply for power failure protection. When the NC power supply is insufficient, the battery needs to be replaced in time to ensure that the data is not lost. However, because the NC system has a memory function, if the operator is operating the machine tool for processing, and other personnel turn off the main power of the machine tool, the machine tool pallet may continue to advance uncontrollably, crash the machine tool, and cause an accident. At the same time, because the NC power supply instantaneous current is too large, it is easy to burn the machine tool. Therefore, CNC machine tools should have their sequence: turn on the external main power supply first, then turn on the machine main power supply, and finally turn on the NC power supply. Turn off the NC power first, then turn off the general power supply of the machine tool, and turn off the external power supply when it is determined that no other machine tools are used, which is the opposite of the startup sequence.

3.Option OK

The Siemens system needs to determine the options from time to time when operating the control panel. During the tool setting operation, when the X-axis or Z-axis tool setting operation is completed, the new data will be displayed on the display. But if you don’t press the “confirm” key, the system still uses the data before tool setting as the required tool compensation value, and does not recognize the newly-paired tool compensation value. At this time, if you use this tool compensation for processing, it is easy to have a tool hitting event.

4.Data Display

If you select “Handwheel mode” in the “JOG” mode, the system will ask for confirmation of the X axis or Z axis. If you do not confirm, the tool post will still move in the previous direction, which may cause the tool post to move incorrectly and cause a collision. Knife situation.

5.Zero offset

In modern CNC system operations, people often use a zero offset command in the G54~G59 belt conveyor to set the position of the workpiece zero in the machine tool coordinate system (the workpiece zero is offset based on the machine zero). When using this method, pay attention to whether tool compensation is used, and which point is used as the reference point to set the tool compensation value. If the displacement from the machine origin to the workpiece is used as the tool compensation value, then the zero offset command will cause a coordinate system positioning error, which will bring danger to the operation. Therefore, once the zero offset command such as G54 is used, it should be noted that the command should be used to cancel the settable zero offset in time after the operation is completed. In the same way, in the FANUC system, there is a “two-color ball of displacement”. The so-called “displacement” means that the program, tool offset, workpiece coordinate system and other values remain unchanged. If the workpiece moves in translation, it is equivalent to the workpiece coordinate system moving in the opposite direction. mobile. This method can be used to process multiple pieces without moving the blank or rebuilding the coordinate system. When using “Working Displacement”, you should cancel its value after use, otherwise other operators will easily cause the wrong positioning of the workpiece coordinate system when operating the machine without knowing it, and it is easy to hit the knife and cause safety accidents.

6.Wear correction

Tool wear compensation means that after the tool has been aligned and the tool compensation value established, the tool wears out after use, and this small amount of wear value is placed at the tool wear compensation place after tool setting. It is suggested that the tool nose wear value can be placed at the wear compensation location, but the tool length compensation value should be placed at the tool length compensation location. Because if the tool change command and tool compensation number are specified in the program, the program executes the tool change command first, and then executes the tool length compensation. The tool wear compensation is just the opposite. The program executes the tool wear compensation first, and then performs the tool change operation. If the wear compensation value is too large, the tool is likely to collide on the machine tool table and cause danger.

7.Z-axis inspection

Most CNC machine tools have graphic verification functions, but most of them are two-dimensional graphic verification. In the Cnc Milling Machine and machining center, only the X-axis and Y-axis graphics can be checked, and the Z-axis value cannot be checked graphically. Therefore, it cannot be considered that the program is correct if the graphics are correct. It is also necessary to test the Z-axis value and check the use of G00 or G01, G02 and other commands to avoid accidents.

8.Program processing

When processing a part program in a Siemens system, you need to select the corresponding program name. If the operator only presses the’Open’ button after clicking the desired program, the work area of the display area will display the program that has just been opened. But the program displayed in the upper right corner is still the program selected for the last automatic cycle processing. At this time, if you press the “Cycle Start” command, the processing program will be the program displayed in the upper right corner, instead of the program you just opened (this Point and the commonly used Windows operating system habits are different), and misprocessing occurs, and even cause safety accidents. The correct operation is that after the operator clicks on the program to be processed, he must press the “Select” key to confirm the selection of the program.

The Operating Procedures Of CNC Grinding Machine

The Operating Procedures Of CNC Grinding Machine

1. The operator is allowed to operate after passing the examination and obtains the operation certificate. The operator should be familiar with the performance and structure of the machine, and must abide by the safety and shift shift system.

2. The operator must understand and memorize each lubrication part, lubrication method and type and brand of lubricating oil in detail according to the requirements of the manual of the powerful grinder, and carry out the lubrication maintenance according to the lubrication chart of the grinder.

3. Before starting work, you should wear protective equipment according to the regulations, check all parts of the grinder in detail according to the transfer record book, and report any problems in time. If abnormal conditions are not eliminated, you should not drive to work.

4. The following parts of the powerful grinder should be inspected before starting work:

- (1) Whether the amount of oil in the oil sump of the wheelhead reaches the specified oil level.

- (2) Adjust whether the belt tightness is appropriate.

- (3) Whether the reciprocating movement of the shaking hand wheel, worktable, and grinding wheel holder is good.

- (4) The protective cover of the grinding wheel and the grinding wheel should be installed firmly, the position is correct, and the dust-proof felt of the worktable guide rail should be in close contact.

- (5) Check whether the electrical system (motor, distribution box, safety light, wire, grounding wire) is in good condition, and whether the surrounding environment is clean and free of short circuits.

- (6) Check each lubrication part, each sliding surface and transmission system, and inject lubricating oil.

- (7) Turn on the power supply, start the motors of the oil pump, the grinding wheel frame, and the headstock in sequence, and pay attention to the running status. If abnormal shapes or sounds are found, the power should be turned off immediately, and the vehicle should be allowed to drive after inspection and treatment.

- (8) Start the grinder and run it idling for 2 to 3 minutes to check whether the movement of each part is normal. If there are abnormal conditions such as mechanism failure, bearing overheating, insufficient oil pressure, grinding wheel swing, unsteady table movement, etc., stop and cut off the power supply and take measures to deal with it. It is strictly forbidden for users to disassemble and deal with it beyond the scope of self-inspection and self-repair.

- (9) Check whether the motor of the cooling pump runs normally and whether the coolant is unblocked.

- (10) When the grinding wheel is installed, a 0.5~1.0mm paper pad should be used between the grinding wheel and the pressure plate. A special wrench must be used to tighten it evenly. No extension pipes are allowed to tighten, so as to prevent the grinding wheel from bursting.

- (11) After the grinding wheel is installed, it should be operated with no load for 5 minutes. The operator should avoid the front and confirm the normal operation of the grinding wheel before using it.

5. The clamping of the workpiece must comply with the regulations. For the workpiece whose processing is interrupted for some reason, it must be confirmed that it is in good condition before starting work.

6. When processing the workpiece, the grease, black dirt and dust on the workpiece must be removed in advance; the grinding wheel and the amount of grinding should be selected according to the material of the workpiece, and it is strictly forbidden to grind the workpiece blank. \r

7. When installing the card and measuring the workpiece, the grinding wheel must be retracted from the workpiece and stopped. When the workpiece and the grinding wheel have not left, do not stop halfway. When the grinding wheel is close to the workpiece, it is not allowed to be sent by motor.

8. When working, it is forbidden for the operator to leave the grinder or take care of it. If it is necessary to leave due to power failure or other reasons, the grinding wheel should be stopped after leaving the workpiece. When restarting the grinder, confirm that there are no abnormalities in all parts before driving.

9. When the grinder is working, pay attention to the status of each transmission part, such as whether the oil temperature and oil pressure are normal, whether the coolant is poured on the workpiece smoothly and accurately, whether the temperature of the oil pump and the motor is normal, whether there are abnormal shapes, abnormal noises, and operating handles Whether the position is correct, whether the fastening parts are loose or shifted, etc.

10. It is forbidden to place metal objects on the work surface and painted surface.

11. It is forbidden to knock, disassemble, and straighten the workpiece on the work surface and bed.

12. After an accident occurs to the grinder, keep the scene, cut off the power supply, report quickly, and deal with it properly.

13. After the work is completed, the grinding wheel should be withdrawn from the workpiece, the main power supply should be cut off, and the handles should be placed in the empty position to restore the normal state of the grinder, and perform routine maintenance.

14. Carefully fill in relevant records such as the handover record book.

Please keep the source and address of this article for reprinting:CNC Grinding Machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machine Wiki,Thanks!^^