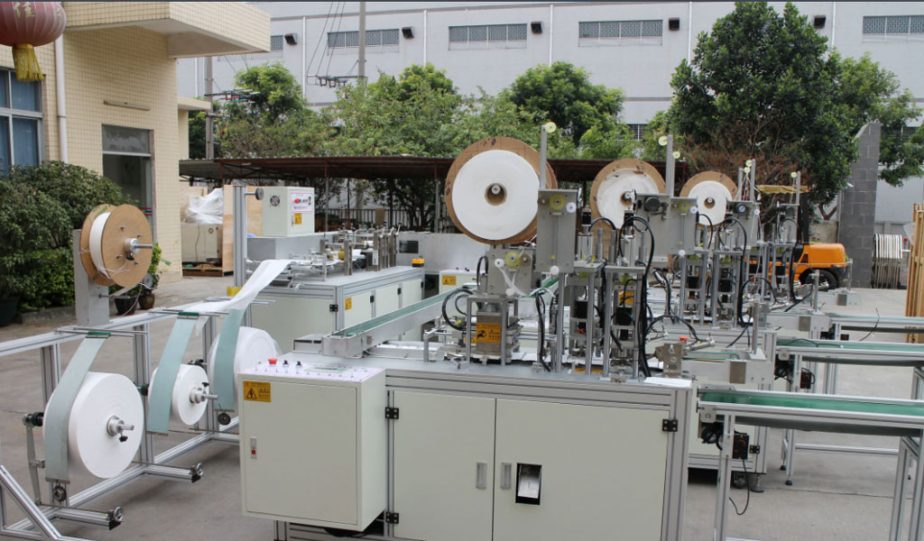

The mask machine is a multi-layer non-woven fabric through hot pressing, folding molding, ultrasonic welding, waste removal, ear strap nose bridge welding and other processes to produce various masks with certain filtering performance. The mask production equipment is not a single machine, it is The cooperation of multiple machines is required to complete various processes. The more popular mask equipment in the market includes: cup mask machine, non-woven flat mask machine, N95 mask machine, 3M9001/9002 folding mask machine, duckbill mask machine, three-dimensional dust mask machine, etc.

Mask machine, a machine for producing masks, the mask machines on the market now include: HD-0301 flat mask machine, HD-0304 cup mask machine, duckbill mask machine, folding mask machine, gauze mask machine, etc.

The flat mask machine series can be divided into: inner ear mask machine, outer ear mask machine, strap-type mask machine according to the welding method and use method of the ear straps. The production of these three types of flat masks requires the use of the mask body machine, which is a It forms an integral part of the flat mask.

- Name: face mask machine, mask machine, mask making machine

- Commodity name: mask machine, cup mask machine, duckbill mask machine, mask machine, etc.

Mass production of various types of masks. Such as: flat masks, cup masks, duckbill masks, etc.

List of Contents

Various Types Of Mask Machine Information

Automatic Cup Mask Machine

parameter:

- Power: 5Kw

- Voltage: 220v

- Weight: 500kg

- Dimensions: 3500 x 1500 x 1800mm

- Efficiency: 20-70/pcs

- Air pressure: 5kg/c㎡

Features Of Automatic Cup Mask Machine

- The advanced servo and constant temperature control system used is controlled by PLC program, so that the material from entering → forming → welding → punching can be completed at one time, and the whole production process is fully automated.

- The equipment only needs to be equipped with an automatic cup-shaped mask nose bridge, ear strap welding machine, and it can produce countless cup-shaped mask products that are sold well in the market.

- The products are exquisitely made, and the quality fully meets or exceeds the domestic and foreign testing standards. At the same time, it saves more than 30% of materials than the previous market mask equipment. Thereby reducing costs and improving efficiency in a real sense.

Fully Automatic N95 Mask Machine

Fully automatic mask body production machine, including feeding, plastic strip aluminum strip insertion/shortening, scene selection, ultrasonic fusion, slicing, etc. The whole process is automatically completed, and the output is extremely high, which can produce 1-200 pieces per minute. The main power frequency conversion speed regulation can be fast or slow. Different materials can be used to produce different masks. The product has two layers and three layers, and the product quality is stable, easy to operate, low noise and small footprint. Applicable material: spunbond filament non-woven fabric, 16-30 g/m² Suitable for processing disposable masks

N95 Cup Mask Machine

Hot-pressing molding: The mask raw material (non-woven fabric) is formed in the form of hot-pressing (cup shape). 1. Including automatic return action and feeding frame; 2. Four masks are formed each time.

Slicing: used to make the outer layer (protective layer of the cup-shaped mask). The special alloy steel is used to make the flower wheel. The knife edge is wear-resistant and has a long life. The eccentric adjustment is flexible, fast and high level. Using ultrasonic waves and special steel Wheel processing, no damage to the edge of the cloth, no need for preheating when manufacturing without burrs, and continuous operation

- Hemming: Laminate the inner and outer layers of the mask

- Trimming: Use pneumatic punching to cut off the excess edges of the mask.

- Breathing valve welding: welding mask breathing valve

- Welding area: 130mm

- Speed: 45/min

The fuselage one-piece structure adopts safe adjustment scale control; the computer intelligent control, the accuracy can reach one thousandth of a second; the mold level adjusts the fuselage motor to automatically rise and fall, and the base level adjusts.

Ear strap spot welding machine: Speed: 8-12 pieces/min It can be used for welding flat face, inner ear strap/outer ear strap, standard mask, duckbill and other special-shaped masks. After the mask body is made, the earbands are manually welded

Flat Mask Machine

The ultrasonic inner ear strap mask machine adopts ultrasonic welding method. When the mask is moved to the processing position, the ultrasonic wave is automatically generated, which forms micro-amplitude and high-frequency vibration on the ear strap, which is instantly converted into heat, melts the material to be processed, and finally makes the ear straps. The tape is permanently pasted or embedded in the inner side of the mask body. It is the last processing process of the inner ear mask production. Only one operator needs to place the mask body piece by piece in the mask tray, and the equipment will automatically operate the subsequent actions until the finished product is completed. .

Workflow: (mask body) manual feeding → automatic feeding of earbands → ultrasonic earband welding → non-woven sideband feeding and wrapping → ultrasonic sideband welding → sideband cutting → finished product output → counting → finished product stacking → conveying Send out with device

Folding Mask Machine

Folding mask machine, also known as C-type mask machine, is a fully automatic machine for the production of folding mask bodies. It uses ultrasonic technology to bond 3 to 5 layers of PP non-woven fabrics, activated carbon and filter materials, and cut out folding masks. Body, can process 3M 9001, 9002 and other mask bodies. According to the different raw materials used, the masks produced can reach different standards such as FFP1, FFP2, N95, etc. The ear straps are elastic non-woven fabrics, which make the wearer’s ears comfortable and pressure-free. The filter cloth layer of the mask has a good filtering effect and can be It is suitable for high pollution industries such as construction and mining.

Functions and Features:

- It can process 3M 9001, 9002 and other folding mask bodies, and it can be processed at one time.

2, PLC automatic control, automatic counting. - Simple adjustment device, easy to change materials.

- The mold adopts the extraction and replacement method, which can quickly replace the mold and produce different types of masks.

Duckbill Mask Machine

The automatic ultrasonic duckbill mask machine (duckbill mask making machine) is a machine that uses the principle of ultrasonic seamless welding to produce duckbill masks suitable for high-polluting industries. The mask body of this machine can use 4~10 layers of PP non-woven fabrics and filter materials (such as meltblown cloth, activated carbon materials, etc.), so that it can produce finished masks with various filter levels such as N95 and FFP2. And this machine has a very high degree of automation, from feeding to finished products are all automated operations in one line: automatic feeding of raw materials, independent nose thread conveying system, and the nose thread can be automatically wrapped in the non-woven fabric, and the edges are automatically folded. And the finished product is cut, and the breathing valve hole can be automatically attached. The finished product produced by this duckbill mask machine has a beautiful appearance; the machine has stable performance, high output, low defect rate and easy operation.

Features of duckbill mask machine:

- Automatic feeding system

- Folding and forming system

- Ultrasonic heat sealing system

- The performance of the whole machine is stable, the production speed is continuously adjustable, the production efficiency is high, up to 60 pieces per minute, the counting is convenient and accurate, the utilization rate of raw materials is high, the operation and adjustment are simple and convenient, the degree of automation is high, and labor costs are effectively reduced.

Please keep the source and address of this article for reprinting:Face Mask Machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Cnc Machine Wiki,Thanks!^^